Temperature probes play an indispensable role across various industries, subtly tucked into processes where precision and accuracy in measuring heat are non-negotiable. These sophisticated instruments range from simple thermocouples to complex resistance temperature detectors, each designed to offer reliable readings essential for quality control and safety. Whether it is monitoring the delicate environment of a laboratory incubator or ensuring the optimal ingredients simmer in a culinary pursuit, temperature probes offer an unblinking eye over thermal conditions. Discovering the underlying principles that make these devices so effective unveils a fascinating intersection of physics and engineering. Keep reading to unwrap the layers of technology behind temperature probes and their critical applications.

Understanding the Basics of Temperature Probes

At the heart of temperature monitoring systems lie temperature probes, playing an instrumental role in many industries. These precision instruments vary widely, each tailored for a specific function, setting, or temperature range. This section will shed light on the diverse spectrum of temperature sensors, each uniquely designed to capture and relay thermal data accurately. Additionally, readers will gain insight into the essential components of a temperature probe, dissecting the sophisticated engineering that empowers countless sectors to meticulously monitor thermal environments.

Exploring the Different Types of Temperature Sensors

Navigating through the array of temperature sensors, one encounters innovations designed for precision across diverse applications: from the robust thermocouple, ideal for high temperatures in industrial settings, to the sensitive thermistor, favored in laboratories for its accuracy in limited temperature ranges.

- Thermocouples: best for high temperature and rugged environments

- Resistance Temperature Detectors (RTDs): known for their precision and stability

- Thermistors: valued for their sensitivity within a narrower temperature scope

- Infrared Sensors: used for non-contact temperature assessment, critical in certain manufacturing processes

- Semiconductor Sensors: offer digital temperature reading, making them a choice for consumer electronic

Unveiling the Core Components of a Probe

Temperature probes consist of several key elements that work in concert to detect and measure heat levels. The sensing element, typically a resistor, thermocouple, or thermistor, responds to temperature changes. Enclosed within a protective sheath, these components connect to a transducer that translates thermal data into readable signals for temperature monitoring systems or a temperature data logger.

The Inner Workings of Thermocouple Probes

Embarking on an exploration of thermocouple probes offers a fascinating glimpse into the practical application of the thermoelectric effect, which is the cornerstone of their function. These devices harness the physics of metal junctions, where the merger of dissimilar metals creates a unique voltage when subjected to temperature variations. This essential interaction furnishes the basis for precise temperature gauging across various environments. By perceiving subtle shifts in voltage corresponding to thermal changes, thermocouple probes are indispensable in realms where accurate temperature data is pivotal.

Related Posts

Temperature monitoring is a multi-billion-dollar industry that is a major aspect of many different businesses. These include hospitals, pharmacies, laboratories, food services, and various chemical manufacturing, to name a few. These businesses rely on accurate temperature monitoring to ensure the integrity and safety of their products. Failing to do so could endanger products and cost your business thousands of dollars (or more) in lost sales or regulatory fines.

With temperature monitoring, information is key. Detecting fluctuations or irregularities allows you to quickly address any potential problems. Wireless temperature monitoring can help you do so more effectively.

The information below lays out everything you need to know about the benefits of wireless temperature monitoring. Keep reading to find out how these technological innovations might allow you to compile and access the information it needs. It also can help you improve your ability to regulate the temperature in sensitive environments.

Temperature Basics

Most people think of temperature in simple terms: how hot or cold something is. To physicists, temperature is a measure of kinetic energy, or the “energy of movement.”

When a substance is heated, its particles absorb some of the heat energy, but the energy also increases the motion of the particles. Going in the other direction, when a substance is cooled, its particles slow down. In fact, it is believed that if a substance were to reach absolute zero (-275℃), it would lack all energy (which is why it may not be achievable).

Temperature is measured using three different degrees. Celsius is used in most of the world for describing the weather, human body temperature, cooking, and other day-to-day situations. In the United States and a few other locations, Fahrenheit is the preference. Kelvin is used in cases of extreme heat or cold, and usually in scientific environments.

What Is Wireless Temperature Monitoring?

Wireless temperature monitoring uses sensors that send temperature data to a centralized system. You can use it in a variety of settings. These include homes; businesses; manufacturing plants; laboratories; clinics and hospitals; or the food production or service industry.

Wireless temperature monitoring systems can range in size, scope, and price. They can use computer software or phone applications, or have their own self-contained programs and monitors that do not require external software or hardware. The type of wireless monitoring system that is best for your business depends on your unique industry needs.

Types of Wireless Monitoring Systems

There are many different types of monitoring systems today. The main differences come in their connectivity, software, and sensor capabilities.

Benefits of Wireless Temperature Monitoring Solutions

Wireless temperature monitoring systems offer several benefits over the most sophisticated wired ones. Here are two major areas to consider.

Convenience

Wireless sensors are easy to set up, as you can mount the sensor in any location. This is convenient, but it also makes them less likely to interfere with the monitored environment. You can also place them in locations where wired sensors may not reach or where the wiring would disrupt the space. This might include coming into contact with the stored materials or being a tripping hazard for personnel. They also are more transportable—relocating them requires little effort or time.

Finally, some wireless temperature tracking systems can be integrated with other environmental monitoring devices. These can include sensors for tracking humidity and differential pressure. You can couple them with devices to track the presence of oxygen, carbon dioxide, or other gases in the environment.

Cost-Effectiveness

Remote monitoring can be a huge plus for many businesses and industries. It can reduce or eliminate the need for frequent checks on the system. This can translate to serious time savings for your staff and associated costs. Wireless monitoring systems can be much more cost effective than traditional ones. They do not require installing wiring or special infrastructure for setup.

Precision

The best wireless temperature monitoring systems also incorporate the most up-to-date sensors and other equipment. This is especially important for businesses that demand precise degree readings in their heated or cooled environments. Being able to access historical data allows you to drill down on fluctuations and determine the causes. This can help you develop solutions for creating a more stable temperature in the environment. It is a good way to help put in place the best temperature monitoring practices in your office, warehouse, or laboratory.

Precision and improved performance can not only help you ensure the integrity of your product but meet regulatory standards for your industry. This includes FDA guidelines for pharmaceutical, scientific laboratory, and food safety. This also can help you avoid a potential shutdown or subsequent fines for failing to do so.

Accessibility

Going with a cloud-based wireless temperature monitoring system can yield huge advantages. The ability of your staff to monitor the system from anywhere has many benefits.Remote staff can use it to document temperature changes or write reports. Staff can receive alerts on temperature fluctuations outside a prescribed range. It can give you the peace of mind that the environment you are monitoring is within the needed temperature range. It also frees up staff from having to regularly check the environment for temperature changes.

Versatility

Wireless monitoring systems also have diverse applications. While they are typically used for measuring air temperature, you can use them to measure equipment as well, or the surface of almost any device or component. This is also the case for monitoring the temperature of solutions, such as vaccines or other pharmaceutical products. Wireless monitors might come equipped with probes that you can insert directly into vials. This allows you to get a more accurate reading of the contents (versus the temperature of the surrounding environment).

Temperature monitoring is a multi-billion-dollar industry that is a major aspect of many different businesses. These include hospitals, pharmacies, laboratories, food services, and various chemical manufacturing, to name a few. These businesses rely on accurate temperature monitoring to ensure the integrity and safety of their products. Failing to do so could endanger products and cost your business thousands of dollars (or more) in lost sales or regulatory fines. With temperature monitoring, information is key. Detecting fluctuations or irregularities allows you to quickly address any potential problems. Wireless temperature monitoring can help you do so more effectively. The information below lays out everything you need to know about the benefits of wireless temperature monitoring. Keep reading to find out how these technological innovations might allow you to compile and access the information it needs. It also can help you improve your ability to regulate the temperature in sensitive environments.

Temperature Basics

Most people think of temperature in simple terms: how hot or cold something is. To physicists, temperature is a measure of kinetic energy, or the “energy of movement.” When a substance is heated, its particles absorb some of the heat energy, but the energy also increases the motion of the particles. Going in the other direction, when a substance is cooled, its particles slow down. In fact, it is believed that if a substance were to reach absolute zero (-275℃), it would lack all energy (which is why it may not be achievable). Temperature is measured using three different degrees. Celsius is used in most of the world for describing the weather, human body temperature, cooking, and other day-to-day situations. In the United States and a few other locations, Fahrenheit is the preference. Kelvin is used in cases of extreme heat or cold, and usually in scientific environments.

What Is Wireless Temperature Monitoring?

Wireless temperature monitoring uses sensors that send temperature data to a centralized system. You can use it in a variety of settings. These include homes; businesses; manufacturing plants; laboratories; clinics and hospitals; or the food production or service industry. Wireless temperature monitoring systems can range in size, scope, and price. They can use computer software or phone applications, or have their own self-contained programs and monitors that do not require external software or hardware. The type of wireless monitoring system that is best for your business depends on your unique industry needs.

Types of Wireless Monitoring Systems

There are many different types of monitoring systems today. The main differences come in their connectivity, software, and sensor capabilities.

Connectivity

By their nature, wireless temperature monitoring systems need a wireless means for transmitting information. The most common type is through a Wi-Fi connection. A big benefit of this setup is that it ensures real-time relaying of data, rather than devices storing information for later download. It also means you can access the information from almost any location. Some systems use Bluetooth capabilities, usually in addition to (rather than in place of) Wi-Fi connections. These are most common in smaller areas where data does not need to be sent long distances to a central monitor or computer. There also are monitoring systems that use cellular signals for transmitting signals. This can be particularly useful for applications where Wi-Fi is not readily available. Finally, some systems rely on their own connection signals to send data. These are often some type of radio frequency. This can be beneficial for heightened security, where you do not want sensitive information accessible via the internet. Note that most wireless temperature monitoring systems include some type of encryption and other safety measures. This makes them secure, regardless of the method of data transmission.

Software

Wireless temperature monitoring systems come with different software configurations. Some can integrate with other monitoring programs or rely on separate software for accessing data. Many wireless temperature monitoring systems have their own operating systems that require no external software. These can still be cloud-based, and offer the other benefits of remote monitoring and notifications, but can also be used as stand-alone devices. This also can offer heightened security, since there are no external programs accessing the data.

Sensors

The other major distinction among wireless temperature monitoring systems is the sensors. There are three main types to consider, and each has its own distinct advantages and a few drawbacks. Here are some assets (and deficits) to consider.

Thermocouples

Thermocouples are temperature sensors that generate a voltage that is proportionate to the temperature difference between two metal components. They are often used in a variety of industrial, engineering, and scientific settings and can measure a wide range of temperatures. Thermocouples work by measuring electromotive force. This is the voltage generated when two distinct metals join together at two separate points. This is commonly known as the Seeback Effect. One of the biggest advantages of thermocouples is that you can use them in very high or low temperatures, as well as in demanding environments. For instance, some can measure up to 4,200℉ and as low as -450℉, which can surpass the limits of many other types of sensors. They also have a very fast response time, which can be important in certain applications.

In general, thermocouple sensors are very durable. They are self-powered, so they do not need an electrical source to operate (although this may not be the case with wireless sensors that rely on this method). They also have a simple design, which makes them inexpensive. There are some drawbacks to thermocouples as well. They are not as accurate as other types of sensors, including resistance and temperature detectors. That is because they can experience “temperature drift” over time. This is where, for the same given physical quantity being measured, the sensor output varies at different temperatures. Thermocouples are less linear than other types of sensors. Linearity reflects the ability of a sensor to respond to changes in a measured variable across a wide range of temperatures. Also, while rugged, if thermocouples are not insulated properly, they may be susceptible to corrosion over time.

Thermistors

Thermistors are electronic components used to measure temperature. They function in a similar way to thermocouples: by using resistance to determine temperature. There are two types of thermistors. Negative temperature coefficient thermistors have a resistance that decreases as temperature increases. Positive temperature coefficient thermistors have a resistance that goes up with increased temperature. Thermistors are ideal for sensing controlled applications. These include many home thermostats and thermometers, but they are used in some industrial or medical settings as well. They are usually very small and are highly sensitive. This has the advantage of a quick response time, but the drawback of them working better over a smaller temperature range. (I.e., they become less accurate in situations with more dramatic temperature swings.) Like thermocouples, thermistors are nonlinear. This too makes them less suitable for large temperature ranges. They also are more fragile than both thermistors and resistance temperature detectors. Finally, they are more susceptible than other sensors to errors related to self-heating.

Resistance Temperature Detectors (RTDs)

Resistance temperature detectors use a thin metal wire that has a predictable alteration in electrical resistance. This measures temperature relative to these changes. Most RTDs use platinum, nickel, or copper to achieve readings. RTDs are very common in a variety of industrial uses. These include chemical plants; petroleum and chemical refineries; power generation facilities; and HVAC systems. RTDs are also found in many scientific research and aerospace applications.

RTDs are extremely stable and linear, which gives them a broad application. Across the board, they are more accurate than other sensors, including thermocouples and thermistors. RTDs do need an electrical source, which is usually not an issue for most applications. They are self-heating, which can have a small impact on the environment in which they are monitoring. A final drawback is that they can be much more expensive than other sensors, although their capabilities can more than make up for the extra cost.

Benefits of Wireless Temperature Monitoring Solutions

Wireless temperature monitoring systems offer several benefits over the most sophisticated wired ones. Here are two major areas to consider.

Convenience

Wireless sensors are easy to set up, as you can mount the sensor in any location. This is convenient, but it also makes them less likely to interfere with the monitored environment. You can also place them in locations where wired sensors may not reach or where the wiring would disrupt the space. This might include coming into contact with the stored materials or being a tripping hazard for personnel. They also are more transportable—relocating them requires little effort or time. Finally, some wireless temperature tracking systems can be integrated with other environmental monitoring devices. These can include sensors for tracking humidity and differential pressure. You can couple them with devices to track the presence of oxygen, carbon dioxide, or other gases in the environment.

Cost-Effectiveness

Remote monitoring can be a huge plus for many businesses and industries. It can reduce or eliminate the need for frequent checks on the system. This can translate to serious time savings for your staff and associated costs. Wireless monitoring systems can be much more cost effective than traditional ones. They do not require installing wiring or special infrastructure for setup.

Precision

The best wireless temperature monitoring systems also incorporate the most up-to-date sensors and other equipment. This is especially important for businesses that demand precise degree readings in their heated or cooled environments. Being able to access historical data allows you to drill down on fluctuations and determine the causes. This can help you develop solutions for creating a more stable temperature in the environment. It is a good way to help put in place the best temperature monitoring practices in your office, warehouse, or laboratory. Precision and improved performance can not only help you ensure the integrity of your product but meet regulatory standards for your industry. This includes FDA guidelines for pharmaceutical, scientific laboratory, and food safety. This also can help you avoid a potential shutdown or subsequent fines for failing to do so.

Accessibility

Going with a cloud-based wireless temperature monitoring system can yield huge advantages. The ability of your staff to monitor the system from anywhere has many benefits. Remote staff can use it to document temperature changes or write reports. Staff can receive alerts on temperature fluctuations outside a prescribed range. It can give you the peace of mind that the environment you are monitoring is within the needed temperature range. It also frees up staff from having to regularly check the environment for temperature changes.

Versatility

Wireless monitoring systems also have diverse applications. While they are typically used for measuring air temperature, you can use them to measure equipment as well, or the surface of almost any device or component. This is also the case for monitoring the temperature of solutions, such as vaccines or other pharmaceutical products. Wireless monitors might come equipped with probes that you can insert directly into vials. This allows you to get a more accurate reading of the contents (versus the temperature of the surrounding environment).

Maintaining proper storage conditions for raw materials, in-process products, and finished goods is critical in the highly regulated pharmaceutical industry. Temperature mapping, a key component of GMP (Good Manufacturing Practice) temperature validation, helps ensure that your storage facilities meet strict regulatory requirements. Let’s explore why temperature mapping is essential and how to implement it effectively.

What is Pharmaceutical Temperature Mapping?

Temperature mapping is the process of measuring and documenting the temperature distribution within a storage area over a set period. This detailed spatial mapping provides a comprehensive understanding of temperature variations, identifies hot and cold spots, and helps validate that the storage environment is suitable for the products stored within.

Why is Temperature Mapping Important?

- Regulatory Compliance: Regulators like the FDA require documented evidence that pharmaceuticals are stored under appropriate conditions. Temperature mapping is a crucial part of demonstrating compliance with GMP standards.

- Product Quality and Safety: Many pharmaceutical products are temperature-sensitive. Improper storage can lead to degradation, reduced efficacy, or even patient safety risks. Temperature mapping helps ensure product integrity.

- Cost Savings: Identifying and addressing temperature excursions early can prevent costly product losses and potential recalls.

How to Conduct Temperature Mapping

- Define the Scope: Determine which storage areas need to be mapped, considering factors like product sensitivity, storage duration, and regulatory requirements.

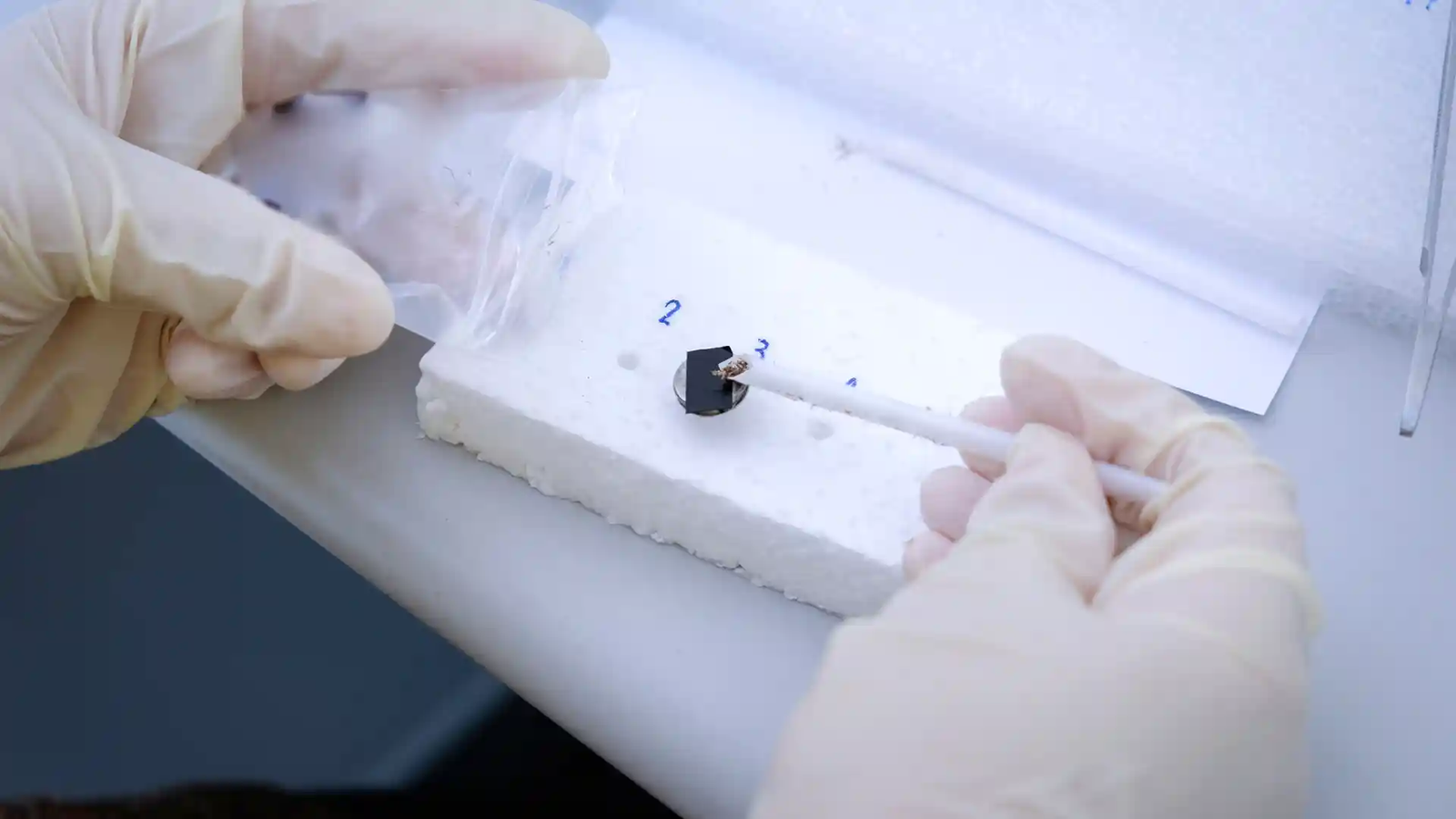

- Select Appropriate Equipment: Use calibrated temperature sensors and data loggers that meet industry standards. Consider factors like accuracy, resolution, and data storage capacity.

- Develop a Protocol: Create a detailed plan that outlines sensor placement, mapping duration, data collection frequency, and acceptance criteria. The protocol should be based on risk assessment and regulatory guidelines.

- Execute the Mapping Study: Place sensors according to the protocol and collect temperature data over the specified period, typically 24-72 hours. Monitor for any excursions and investigate their cause.

- Analyze and Report: Review the collected data, identify any temperature variations, and determine if the storage area meets acceptance criteria. Generate a detailed report that includes raw data, analysis, and conclusions.